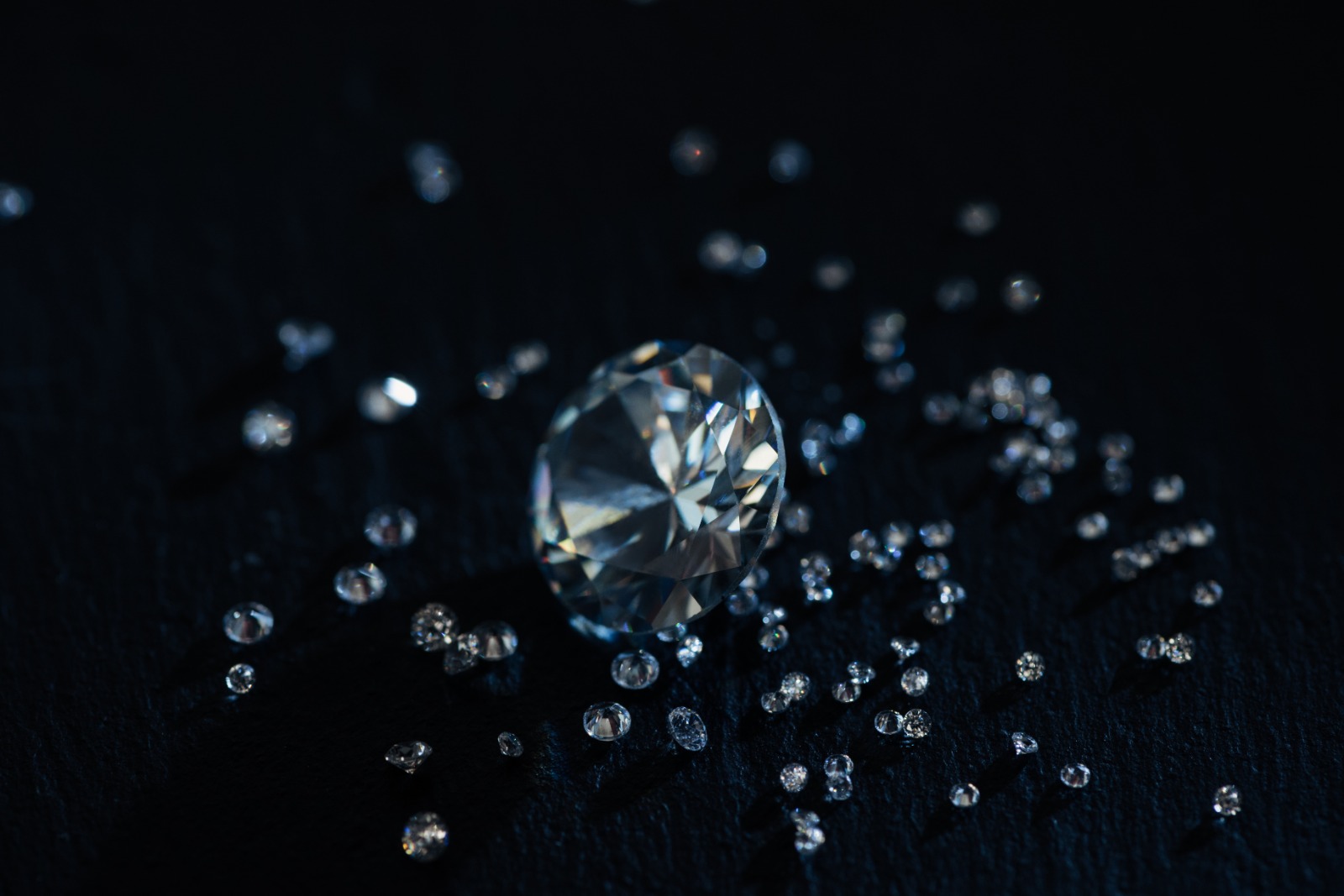

A ground – breaking discovery could make diamonds more accessible and affordable, benefiting both consumers and various industries.

In an astonishing scientific breakthrough, researchers in South Korea have developed a method to produce diamonds in just 15 minutes. This innovation has the potential to drastically reduce the cost of diamonds and expand their availability, making these precious gems as common as cubic zirconia. The implications of this advancement could be profound, both for the jewellery market and various industrial applications.

Traditional Diamond Formation vs. New Method

Traditionally, diamonds form deep within the Earth under immense pressure and scorching temperatures. Synthetic diamond production, which mimics these conditions, typically involves high pressure high temperature (HPHT) processes that are complex, time-consuming, and limited in the size of diamonds they can produce.

However, the team led by Professor David Ruoff has revolutionized this process. Their novel approach uses a special chamber operating at normal atmospheric pressure. In this chamber, superheated, carbon-rich gas flows through and interacts with a mixture of gallium, silicon, and other elements heated by electricity. Remarkably, within minutes, diamonds begin to form.

“For over a decade I have been thinking about new ways to grow diamonds, as I thought it might be possible to achieve this in what might be unexpected (per ‘conventional’ thinking) ways,” Ruoff said. This innovative thinking has indeed paid off, challenging long-held assumptions about diamond formation.

Current and Future Applications

While the initial diamonds produced using this method are microscopic and unsuitable for jewellery, their potential uses are vast. Due to their exceptional hardness, these tiny diamonds could be used in polishing tools, industrial drills, and other applications where durability is essential.

The method’s ability to produce diamonds without the need for extreme pressure could pave the way for large-scale diamond production. This scalability is particularly promising for industries that rely on diamond-coated tools and components, offering a more cost-effective and efficient means of manufacturing.

Public Benefits

For the general public, this breakthrough holds several significant benefits:

- Affordable Jewellery: The reduced cost and increased availability of diamonds could make diamond jewellery more affordable for consumers. This democratization of diamonds means more people can enjoy these traditionally expensive gems.

- Industrial Advancements: Cheaper and more accessible diamonds can revolutionize various industries, including manufacturing, electronics, and healthcare. Diamond-coated tools and devices could become more widespread, enhancing performance and longevity.

- Environmental Impact: Traditional diamond mining has significant environmental and ethical concerns. Synthetic diamonds produced using this new method could reduce the demand for mined diamonds, leading to less environmental degradation and better ethical standards.

Economic and Industrial Transformation

The future of this technology is bright. As researchers continue to refine the process, the potential for more efficient and scalable diamond production is undeniable. In the coming years, this breakthrough could transform not only the diamond market but also numerous industries that utilize diamonds for their unparalleled properties.

This innovative approach to diamond production signifies a major leap forward in material science, promising to make diamonds a more common and affordable resource. As the technology matures, it stands to benefit consumers, industries, and the environment alike, heralding a new era in the creation and use of these precious gems.

Leave a Comment